Precisin CNC spinning

10+years spin forming technology

Advanced CNC spinning machine

What is metal spinning

What is metal spinning

Mold

Roller

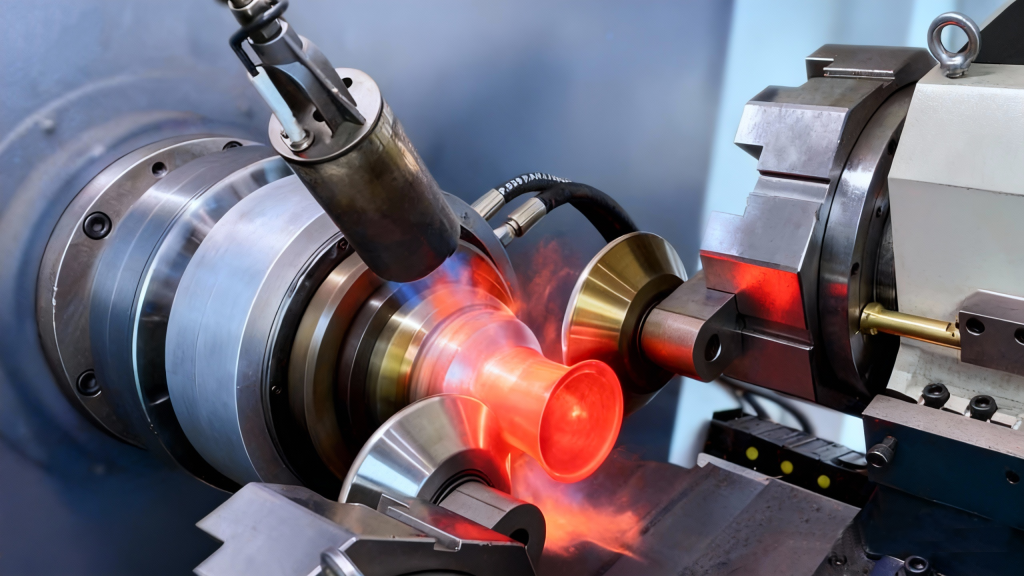

Metal spinning is a metal working process that can make a metal disc or sheet deform different shape of revolving body in a lathe or machine. The mold (it is also called mandrel) and clamp provide the clamping force and take the sheet to spin. When the spinning roller touch and press the sheet according to the spinning path, the sheet will produce plastic deformation from the point to the line follow the spinning roller.

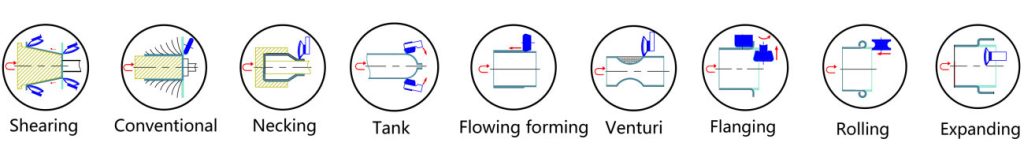

Spin forming technology, tolerance, performance are related to many process parameters and factors, such as the accuracy of CNC spinning machine, mold design, spinning path, roller radius, spindle speed, feed speed, spinning temperature, thinning rate. At same times, the tensile strength, hardness, ductility, spring back of blank materials decides the difficulty of spin forming. The spinning processing method is flexible and changeable, you can choose conventional, shearing, necking, flanging, hemming, flow forming according to the structure and characteristics of different spun products. Welcome to Dinnovation, Let us take you go to the world of spin forming technology.

Metal spinning company

Dinnovation is located in China, Factory building covers an area of 1800 square meters. We invest 8 CNC spinning machines and other fabrication machines such as rolling, deep drawing, flanging, welding, 5 axis laser cutting. There are 16 members in our team, we continually try and test the different material and fabrication ways to promote the development of metal forming technique. Advanced machines and excellent resources support your phases of your production needs. We successfully supply the venturi, funnel, fireplace /firebowl, container /tank, turbine /turbojet, burner nozzle, Combustion chamber, combuster, signal reflecter, military and aerospace components in the market, the export value of spun parts are more than 200,000 pieces every year.

Application

Metal spun products have good tensile strength and hardness after pressing and shearing, it is widely used in the manufacturing. Now Dinnovation supplies more than 200 types of industries, we are expert in precision metal spin forming, to give the appropriate advice to finish your project, it greatly saves customer’s time and mold cost. Our metal spun product Max diameter is 1300mm, Max Heigh is 800mm, Max thickness 15mm, Min tolerance is 0.2mm.

In addition to aluminum, copper, brass, iron, stainless steel sheet spinning, Dinnovation has achieved good applications in the hot spinning of special material such as Superalloy (high-performance alloy), Inconel 718 and 625 (nickel-basedf superalloys), Hardox (high wear-resistance), aerospace grade Aluminum 2024 and 7075, these metal have high tensile strength and hardness. From 2019, Dinnovation has a big breakthrough in tube spinning, we have spun 8-14 inches of stainless steel venturi valve, the aluminum 6061 oxygen and hydrogen tank with heating.

Advantage and solutin

Double roller CNC spinnning

5 axis laser welding

Polishing and brushed

5 axis laser cutting

Dinnovation is perfect CNC metal spinning supplier as your choice. Excellent technical abilities and complete metal forming solution to supply the challenging and precision spun parts, more different machines be invested to promote production efficiency and reduce the sample lead time, experienced engineering designer and spinners have worked together for 12 years, standard quality control is our confident to serve our customer. Dinnovation can satisfy every customer from product design to structure analysis, from fabrication to assemblies, from production to quality control. Dinnovation will be your good partner when you need to customize the metal spun products.

Spun metal parts

The major country : America, German, Israel, Korea, Malaysia, Portugal, UK, France, Spain, Ireland, Turkey, Japan, Netherlands, Italy, Canada, New Zealand, India, Vietnam.

Total export value : 20000 pieces of metal spun products every year.

Industries : 200 kinds of insdustries in total.

The fabrication and process : spun metal, deep drawing, CNC, stamping, 5-axis laser cutting and welding, CNC milling and turning.

Precision industries

Aircraft : Turbine Turbojet Combustor Tailpipe Tail-jet Fairing Nozzle

Aerospace : Combustion chamber Oxygen-tank Nozzle

Military parts : Missile Liner Reflector Rada

Hot products

Combustion chamber

Turbojet/turbine

Airplane faring

Aircraft tail nozzle

Dropping funnel

Venturi

Services

Prototyping

To ensure a successful design, we offer the deep drawing and metal spun prototyping services, our engineer will use CAD or UG software to design and adjust for customer.

Design suggestion

We can give you some suggestion when we get your drawing, we can analysis structure, strength and tolerance of your spun product. Then giving you a right suggestion of design adjustment.

Request a quote

Our quotation includes lead time, manufacturing details, mold cost and unit price. It’s a good reference standard.

Testing and quality

Three-dimensional + Inspection tool : We will inspect and test the dimension tolerance of metal spun products.

Testing standard

Quality standard

ISO-9001 : Air pressure welding testing, VT, PT, RT welding testing.

Blog

Discover industry insights and helpful information for your next project .A place to learn and communicate metal spun forming technology and issues.

Top twelve metal forming fabrication methods

Metal forming is mainly used for the production of thin-walled metal parts, such as shells, containers, boxes, casing and other products. Metal forming technology is widely applied in manufacturing. The common metal forming methods we see include hydraulic stretching, spinning, water expansion forming, stamping, bending, pipe bending, aluminum extrusion, hot forging, and hand forging. For many purchasers and designers in the mechanical industry, they are not very familiar with these metal forming methods……

Read more >

What is CNC metal spinning machine tool

CNC metal spinning machine is an equipment to make metal form different shape according to CNC path, The structure is similar with CNC turning lathe, but CNC metal spinning machine have quicker feed speed and stronger torque and process force, CNC turning lathe have higher spindle rotational speed. CNC metal spinning machine tool not only can form the blank sheet by metal spinning roller, but also can use the turning tool to cut the edge……

Read more >

Aerospace components-Precision manufacturing of CNC spinning

When we talk about metal spinning, many people are not unfamiliar with it. Metal spinning is widely used in the civilian field, we can see the presense of spun products in both home and hotels settings, such as lamp shadow, stainless steel tableware, bottle, vase. Many people are confused what fields and components metal spinning can process in the aerospace……

Read more >

Contact us

.

Let’s get started! Please fill out the form to let Dinnovation assist you with any questions about the design of metal spun products, our abilities and experience can help you save the cost.